Requirements

Product requirements:

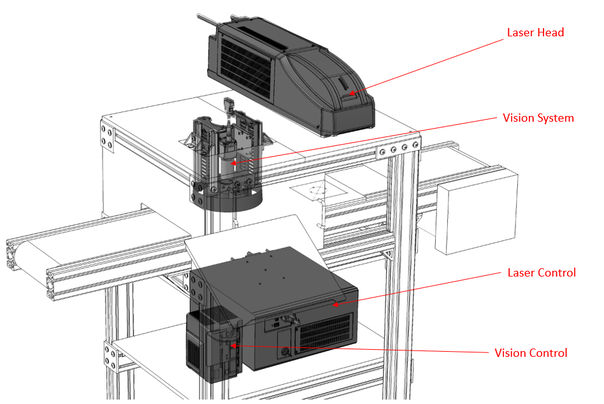

• to securely mount CO2 laser and Keyence optical system

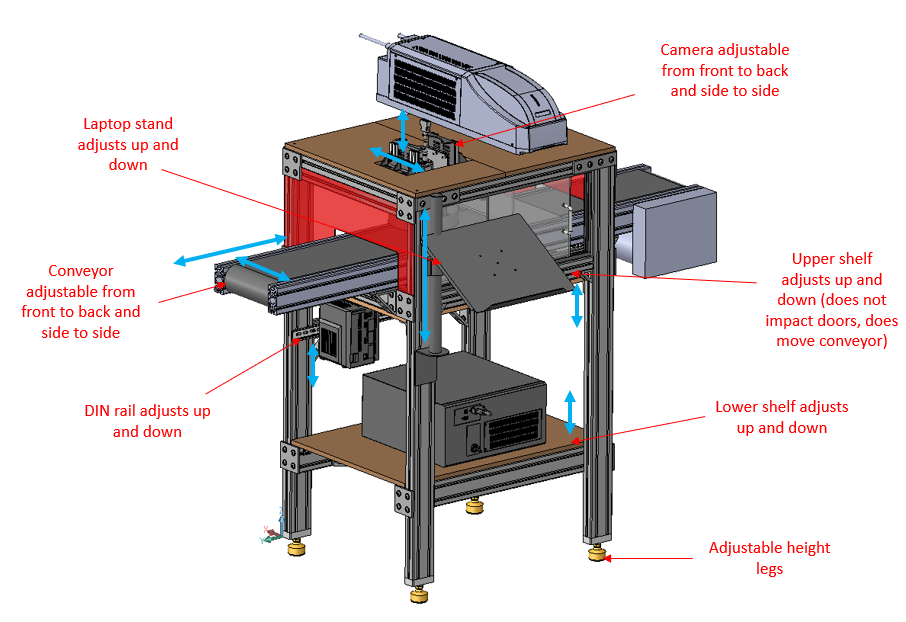

• to allow future adjustment and placement of components

• The ability to mark all parts with varying dimensions

• Future proof it. Ability to progress from manual operation to automation in stages

• Consider part singularity, edge detection, conveyor speed, safety, portability

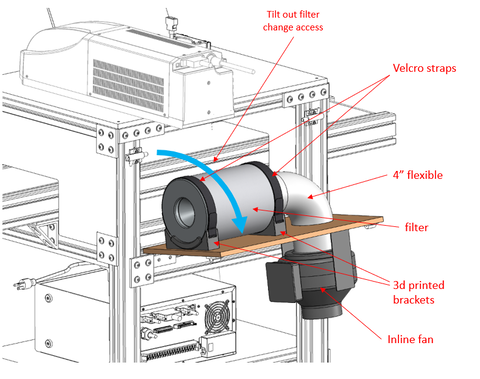

• Fume/ Ventilation system

• Ergonomics of operator

• to securely mount CO2 laser and Keyence optical system

• to allow future adjustment and placement of components

• The ability to mark all parts with varying dimensions

• Future proof it. Ability to progress from manual operation to automation in stages

• Consider part singularity, edge detection, conveyor speed, safety, portability

• Fume/ Ventilation system

• Ergonomics of operator

Design Research

There are a ton of considerations that go into making a new product. This task is harder when there are still many specifics still unknown. This product was an attempt to solve current and future needs while giving us a platform for development along the way.

Cad Development

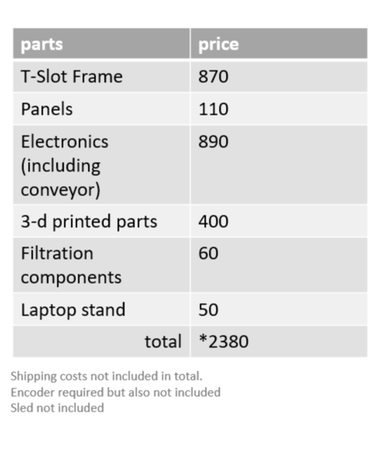

A main driver of this design came from the camera and laser requirements. Each component had a distance they require to be away from the object being scanned or marked. Filtration components were another major influence. Full scale sketches were done along with CAD to verify user access to areas.

Laser Cell Build

Adjustable height laser eye mount with micro adjust. This unit detected parts coming down the conveyor belt by skimming a laser dot across the surface. Also created a jig for hand loaded parts.

Examples of marked parts (left) and Donny (right) hand loading parts in the lab with protective laser shielding...just dangling there.