Product Considerations

- Robust- Protect parts and maintain set continuity

- Clear Visible Labeling- on pallet or rack

- Convey high tech nature of product and support ABT brand

- Optimized for handling and storage at all stages

- Sustainability (no branded trash on job sites)

- End user experience- easy to find correct part

Initial Exploration

I cast the net wide at first but quickly narrowed options down to mostly corrugate. I had physical; samples but helped visualize the concepts for our teams who up to this point had only shipped products in metal pails.

Tuck top boxes (above) or Easy-Fold mailers below were both considered in terms of user experience and also our internal kitting process.

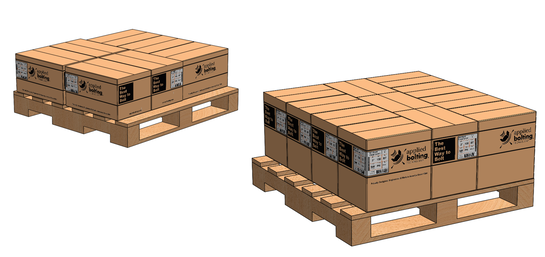

For shipping and warehousing it was important to consider how items would be bulk packed in master cartons as well as palletized

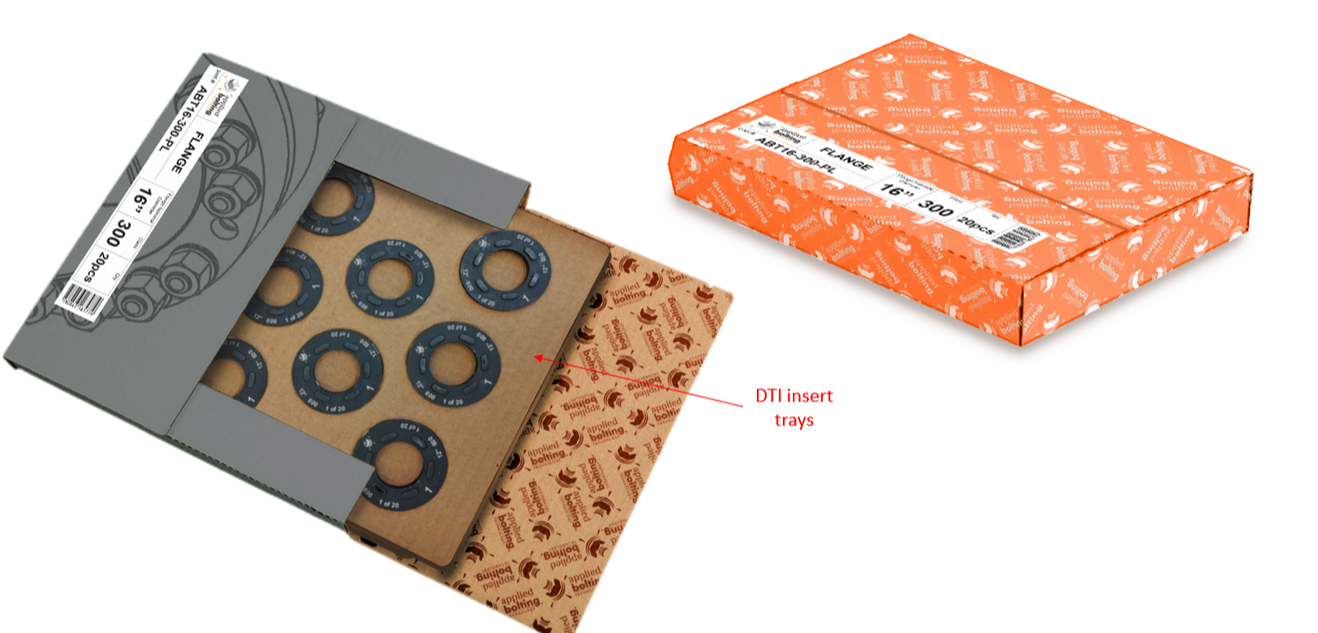

Packaging Design

Based on our part dimension and set quantities, 2 kit boxes and 2 master cartons would be required. A couple vendors were selected to our project and help with final design and details. Prototype tooling off a CNC cutter provided sample parts.

Graphic Design

Applied Bolting has never had images on there product packaging before so several concepts were presented and multiple directions explored. The print plate manufacturer as well as the stamper were brought in to get their feedback from a cost and print quality standpoint.

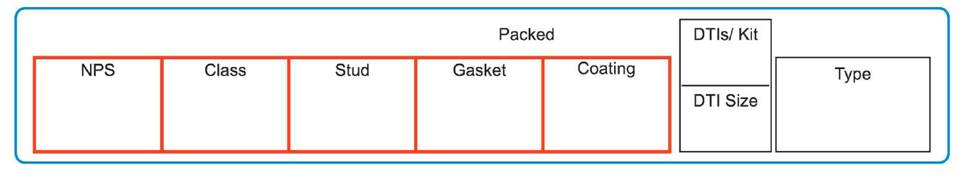

Label development

New product labels provided the opportunity to improve how we conveyed product information internally and to our customers.

Our existing pail label was a jumble of information and lacked hierarchy. Information our new labels would be consumer focused, easier to read, and clearly visible when palletized.

Our existing pail label was a jumble of information and lacked hierarchy. Information our new labels would be consumer focused, easier to read, and clearly visible when palletized.

Label material had to be tested and modified after we noticed edge pealing in our initial production run.

A spool holder was designed and built to accommodate our specific label and roll size

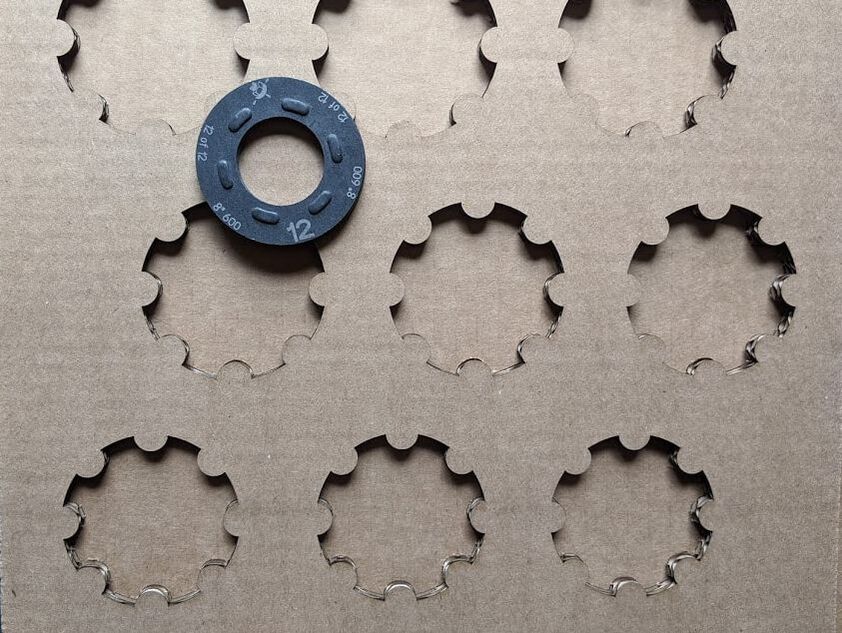

Inserts

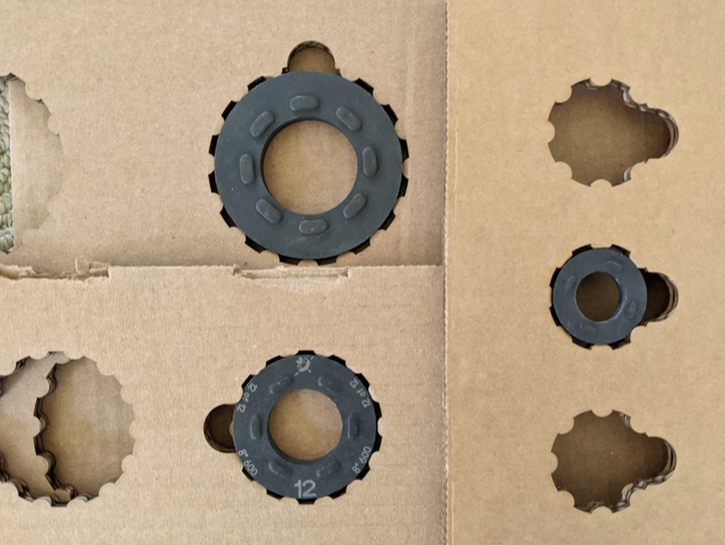

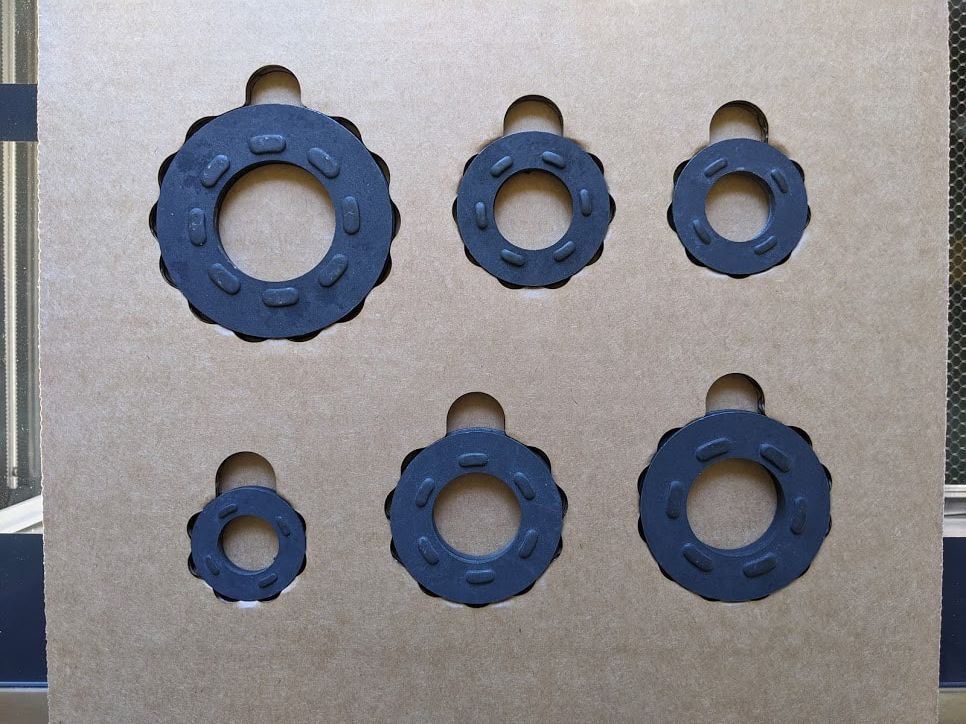

The inserts hold, display, and protect our product within the kit boxes. "They are essentially just a corrugate sheet with a few holes stamped out. Easy."

I was so wrong when I said that.

Below is a small assortment of images showing many of the prototypes and revisions made to these seemingly simple parts. Varying tolerances found in production parts required many redesigns.

I was so wrong when I said that.

Below is a small assortment of images showing many of the prototypes and revisions made to these seemingly simple parts. Varying tolerances found in production parts required many redesigns.

So much lasering...

Ultimately after lots and back and forth with the corrugate stamper, finding a new stamper, working directly with their tooling manufacture, changing the stamping process, making subtle changes to the design, and feeling personally punished for my prior comments, we were finally able to produce a "wavy design" that was easy to manufacture, held our parts, and could compensate for a wide tolerance.

Final Design

And one more thing...

After our new boxes looked so sweet, it was decided that our plain black pails could use a facelift as well. These pails are used for all of our commodity structural fasteners that we sell in bulk.

Below was our current pail next to a mocked up prototype. Design consideration was given to label placement, pallet strapping, and handle to make sure everything played well together.

Below was our current pail next to a mocked up prototype. Design consideration was given to label placement, pallet strapping, and handle to make sure everything played well together.

Final production pail design rolling down the filling line looking fine with its litho print..