R3400 Ridgid Fiber cement saw

Client: TTi

Skills: Industrial Design, Creative Problem Solving, Problem Identification, Mechanical Engineering Project Scope: If inhaled, the dust from fiber cement board can lead to serious medical conditions or death. Our goal was to design a saw that cuts this material minus the cloud of dust, and for roughly the same price as a conventional circular saw.

|

Inventor's prototype

On this occasion the initial idea of a better way to cut fiber cement came from an outside inventor. The unit was crude but clearly showed the potential. Much would have to be address before this prototype could become a commercial product.

Initial concept renderings

The idea was to use existing components for this tool. The general circular saw handle and guard configuration could be paired with a drive-train from an angle grinder giving a solid layout and required 10k RPM blade speed.

Handle Prototypes

The first working prototype incorporated an adjustable handle so we could collect user feedback on optimum handle positioning. Users were instructed to set the handle position where it was most comfortable. Configurations were recorded and implemented into the final design.

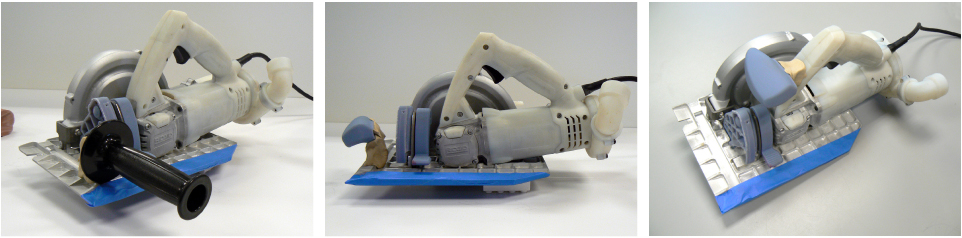

Final prototype

Pommel style and location was refined.

dust collection system prototypes

Final dust collection system

The final design utilized a material called singed needle felt. The material actually improves filtration levels the more it is used and does not cake up like traditional filter bag materials. To keep the packaging size to a minimum, the filter cap was made to install on a standard 5 gallon bucket found on most construction sites.

How it works

Dust is channeled up into a collection shoot built into the saws upper guard. A second fan coupled to the motor acts like a built in vacuum. The dust is sucked into the fan and blown into the collection bucket.

Other advantages

The on-board vacuum system means all needed parts are self contained. The entire saw and filtration system can be carried in one hand making it easier to transport than the competitor's large external vacuum model. Also unique to this product, the unit requires only one electrical plug.